High Velocity Air Jets

Model 6013 and 6013SS High Velocity Air Jets Provides maximum thrust with a confined, directed airstream. It is the best choice for part ejection, chip removal, and part drying.

Model 6013 and 6013SS High Velocity Air Jets Provides maximum thrust with a confined, directed airstream. It is the best choice for part ejection, chip removal, and part drying.

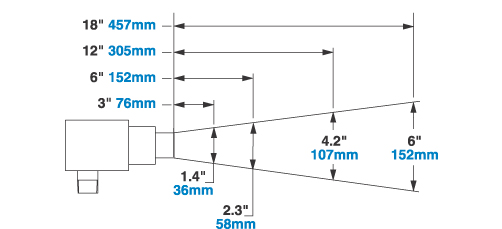

Air Jets utilize the Coanda effect (wall attachment of a high velocity fluid) to produce air motion in their surroundings. As illustrated above, a small amount of compressed air (black arrows) is throttled through an internal ring nozzle above sonic velocity. A vacuum is produced, pulling large volumes of surrounding, or “free” air, through the jet (blue arrows). Both the outlet and inlet can be ducted for remote positioning. If the end is blocked, flow simply reverses at well below OSHA dead end pressure requirements.

Brass - general purpose applications. Maximum temperature 400°F (204°C).

Type 303 Stainless Steel - high temperatures, corrosive environments. Maximum temperature 800°F (426°C).

High Velocity Air Jet Performance | ||||

| Air Consumption | Force | Sound Level | ||

| SCFM | SLPM | Ozs | Grams | dBA |

| 22 | 622 | 20* | 567 | 82 |

| * Force measured at 12" (305mm) from target. Sound level measured at 3' (914mm). All measurements taken at 80 PSIG (5.5 BAR). | ||||

High Velocity Air Jet Models |

||||||||

| Model | Material | Description | Inlet | Air Consumption | Force | Sound Level (dBA) | ||

| SCFM | SLPM | Ozs | Grams | |||||

| 6013 | Brass | High Velocity Air Jet | 1/8 MNPT | 22 | 622 | 20† | 567 | 82 |

| 6013SS | Stainless Steel – Type 303 | High Velocity Air Jet | 1/8 MNPT | 22 | 622 | 20† | 567 | 82 |

| FNPT = NPT Female MNPT = NPT Male. | ||||||||

| † Force measured at 12" (305mm) from target with a .015" (0.38mm) shim installed. | All sound levels measured at 3 feet (914mm) | |||||||

| All measurements taken at 80 PSIG (5.5 BAR) | ||||||||

Material: Type 303 Stainless Steel

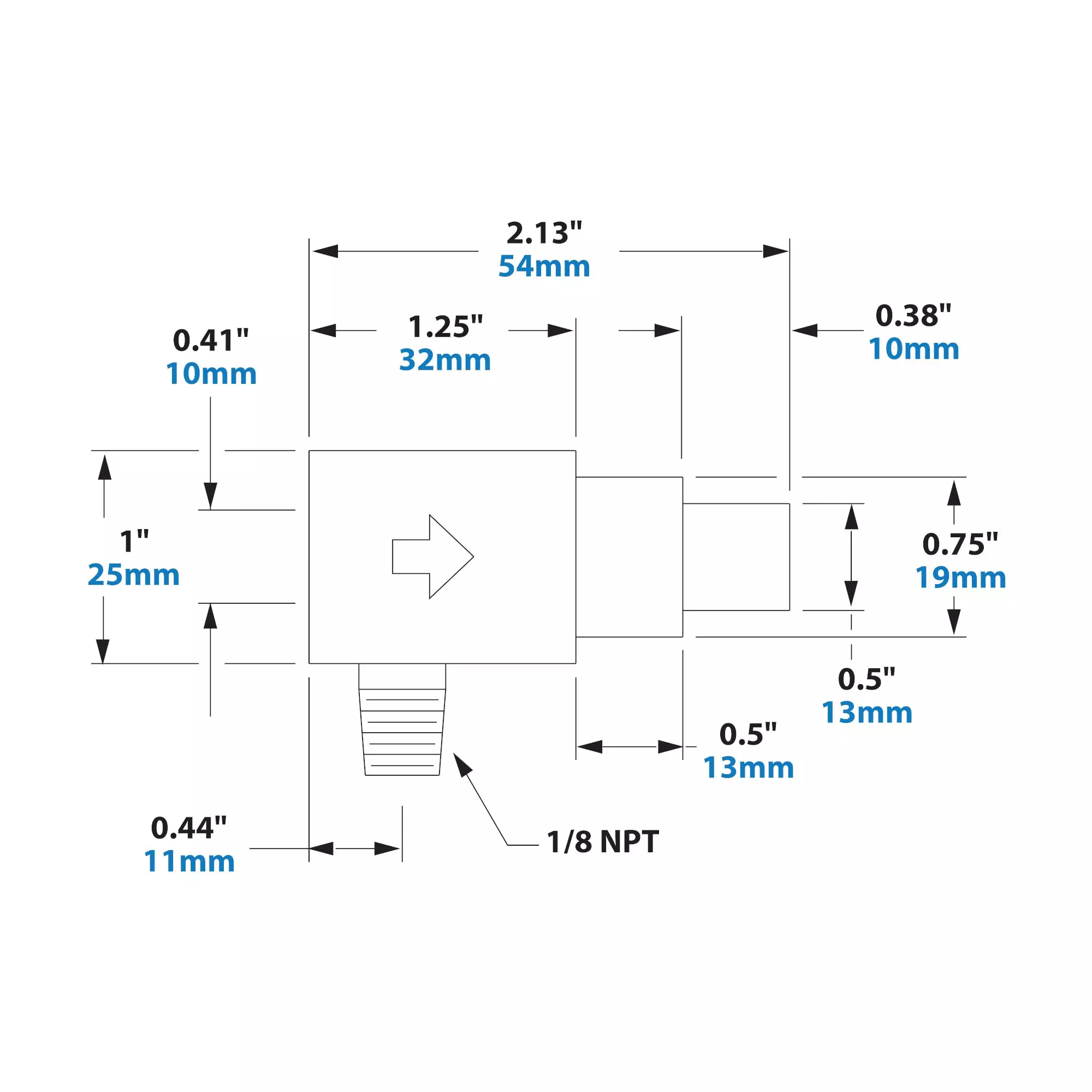

Shims can be used to change the gap on the Model 6013 High Velocity Air Jet. Changing shims will alter air consumption, force, flow and vacuum capability. The Model 6313 Air Jet Shim Set for the High Velocity Air Jet includes a .006" (0.15mm) and a .009" (0.23mm) thick shim. A .015" (0.38mm) shim comes installed with the Model 6013 Air Jet.

- For applications where frequent repositioning of standard force Air Nozzles or Jet is required, the Flexible Stay Set Hoses™ are ideal. Simply mount the hose in close proximity to the application and bend it to aim the airstream at the target. Since the hose has “memory”, it will not creep or bend. It always keeps the aim until physically moved to the next position.

- make it easy to adjust the aim of the Air Nozzles and Jets. Correct placement of the blowing angle can help optimize performance, reduce noise levels and improve efficiency. Swivel Fittings permit a movement of 25 degrees from the center axis for a total movement of 50 degrees. Type 303 or 316 Stainless Steel.

- are suited to applications where frequent movement of the Air Nozzle or Jet is required. The powerful magnet permits horizontal or vertical mounting that will hold the blowing position of the Stay Set Hose. A shutoff valve is provided that can be used to vary the force and flow.

#22, 1st Floor, 1st Cross, Adj. to IIMB Compound, Bilekahalli Indl. Area, Bannerghatta Road, Bangalore, Karnataka,INDIA

#22, 1st Floor, 1st Cross, Adj. to IIMB Compound, Bilekahalli Indl. Area, Bannerghatta Road, Bangalore, Karnataka,INDIA