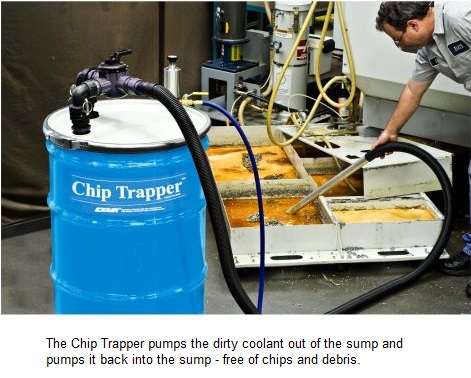

Chip Trapper™ System

The EXAIR Chip Trapper™ System is a powerful and efficient solution for cleaning chips, swarf, and shavings out of used coolants and other liquids. Here are some key features:

- Efficient Cleaning: The Chip Trapper vacuums the coolant or liquid filled with debris and traps all the solids in a reusable filter bag. Only clean liquid is pumped back out1.

- Versatile Applications: Ideal for use on machines with sumps, parts washers, tanks, and storage containers of contaminated liquids.

No Electricity Needed: Operates using compressed air, eliminating the risk of motor failure and making it safe to use with liquids.

Self-Priming Pump: The system includes a self-priming stainless steel pump, ensuring reliable performance.

Drum Sizes: Available in 30, 55, and 110 gallon drum sizes.

Quiet Operation: The Chip Trapper operates quietly, with a built-in pressure/vacuum relief to prevent spills.

Warning: Do not use with any material with a low flash point or with flammable liquids such as fuel oil, alcohol, mineral spirits, gasoline or kerosene.