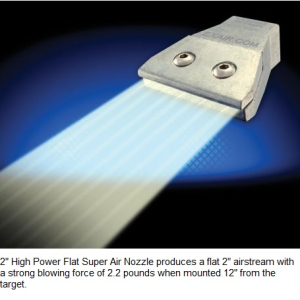

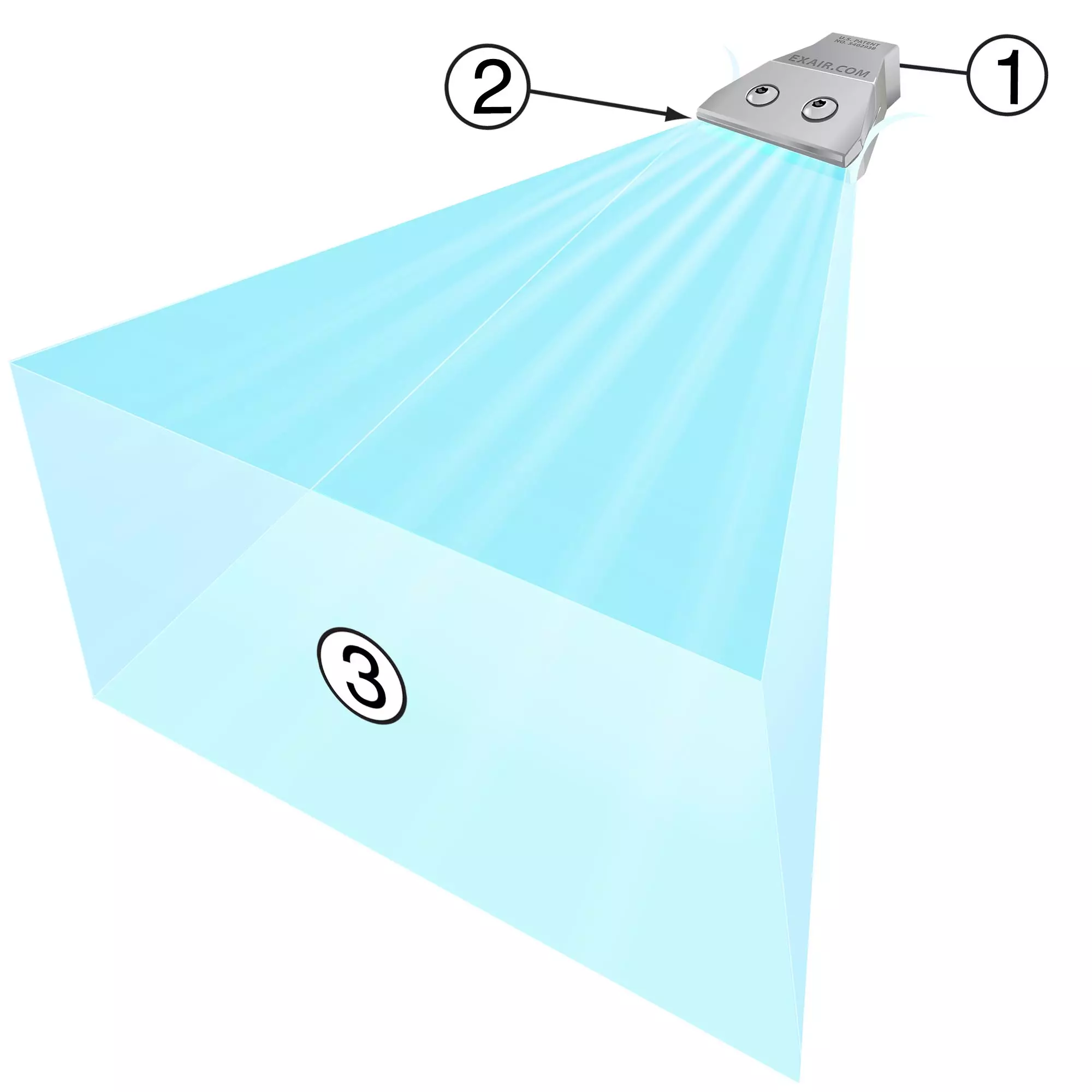

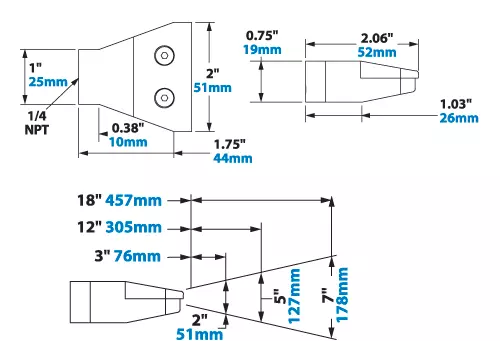

2" High Power Flat Super Air Nozzle™

Model HP1002 and HP1002SS High Power Safety Air Nozzles provide strong blowing force for applications requiring high thrust and velocity. It uses more compressed air than other air nozzles but is low when compared to typical blowoffs delivering the same force.