Safety Air Nozzle

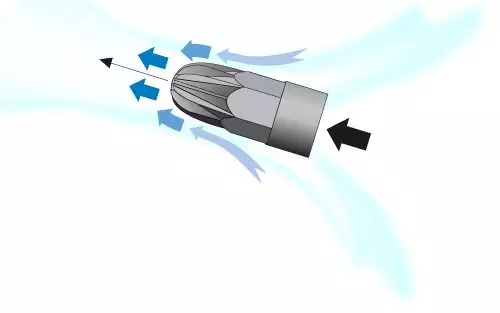

EXAIR's Safety Air Nozzles eject a small amount of compressed air 360° around the outer ring that combines with the air ejected from the center hole to produce a high volume, high velocity blast of air. The slotted end allows air to vent safely and prevents blocking the outlet. EXAIR offers the Safety Air Nozzle in most popular pipe sizes for easy retrofit to existing blowoffs. Available in brass and Type 303 Stainless Steel.