In-Line E-Vac® High Vacuum Kit (Non-Porous)

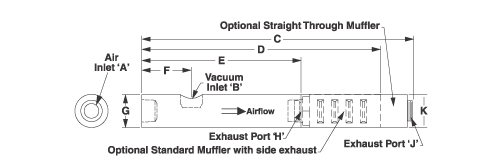

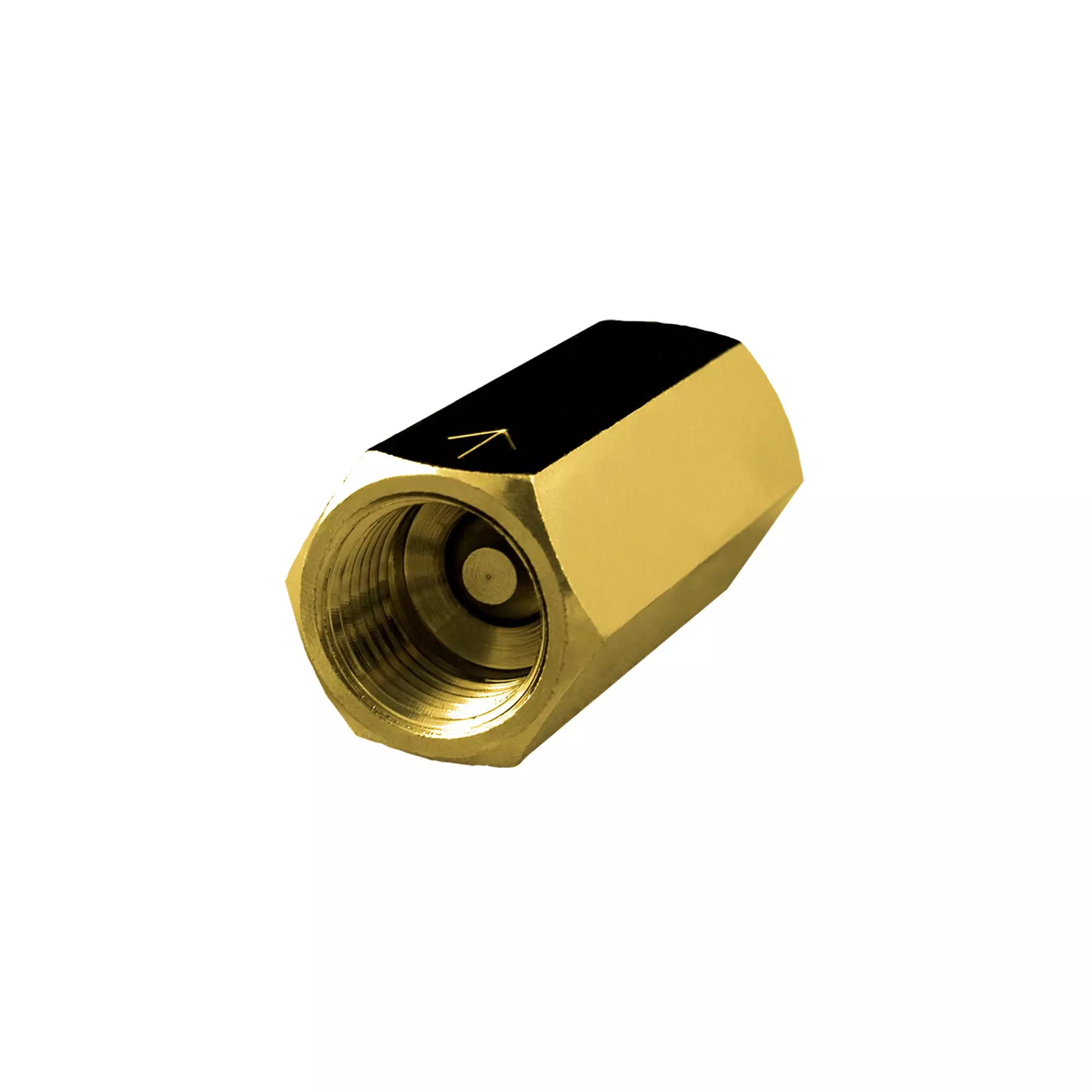

These single stage, cylindrical units are compact and easy to mount at the point of use. Kits include vacuum cups, vacuum fittings and vacuum tube. They can be held in place by threading them directly onto a compressed air line or with the use of a mounting clip. High vacuum units up to 27" Hg (91 kPa) with vacuum flows up to 15.8 SCFM (447 SLPM) are typically used for non-porous materials such as glass, steel sheet and plastic. The Standard Muffler has a closed end and is suitable for applications that are free of dust and debris. The Straight Through Muffler is recommended where particulates are present since it will not accumulate debris that can erode performance. Straight Through Mufflers offer the best sound level reduction (up to 26 dBA).