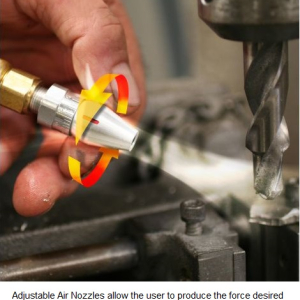

Adjustable Air Nozzles™

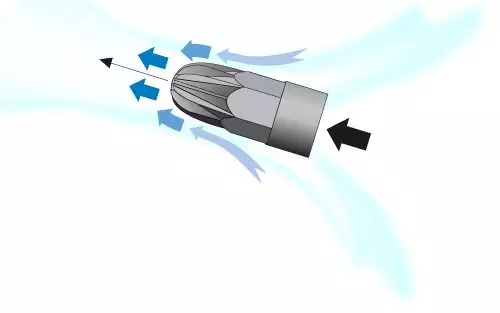

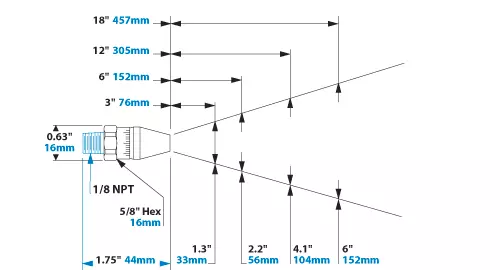

EXAIR's Adjustable Air Nozzles are suitable for a wide variety of blowoff applications. The design allows you to "tune in" the force and flow to the application requirements, thereby minimizing air consumption. A micrometer-like dial indicates the gap setting. A set screw in the end can be tightened so the air nozzle holds the setting. Available in aluminum or 303 stainless steel.