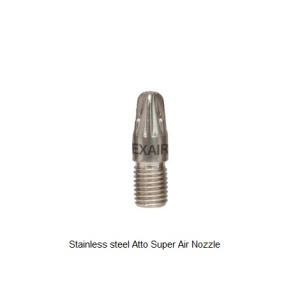

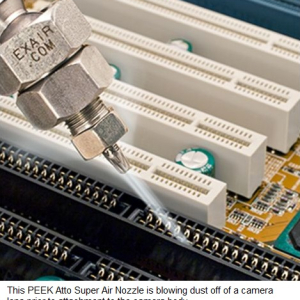

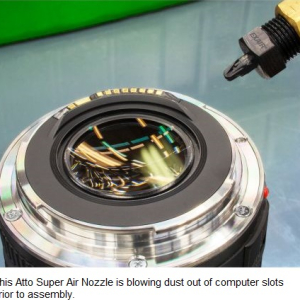

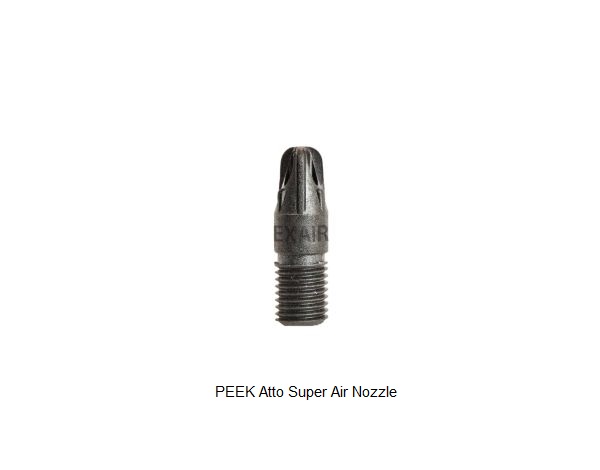

Atto Super Air Nozzle™

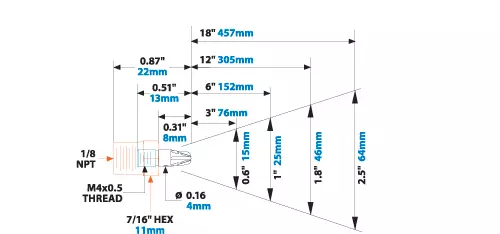

EXAIR’s Atto Super Air Nozzle delivers the smallest, most precise blowoff. The air pattern for this tiny nozzle is focused, measuring 1.0" in diameter when positioned 6" away from the surface. The 58 dBA noise level is a fraction of ordinary air nozzles.