No Drip Internal Mix Flat Fan Pattern Air Atomizing Nozzle

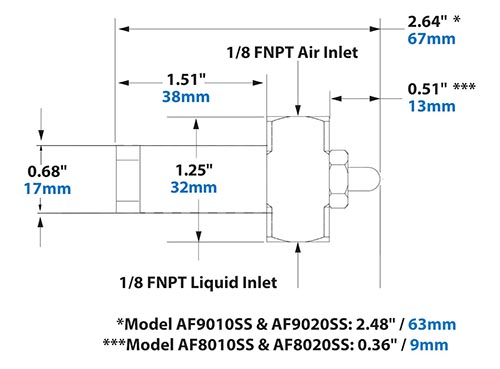

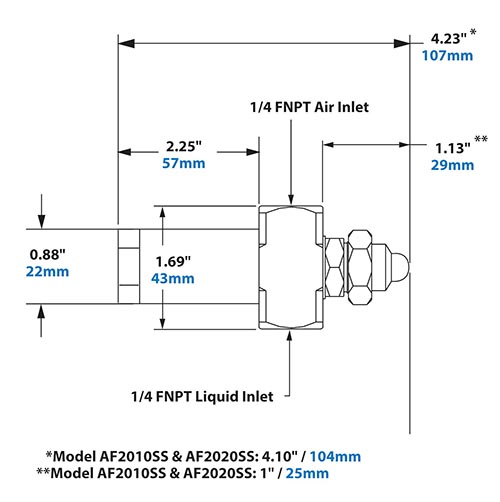

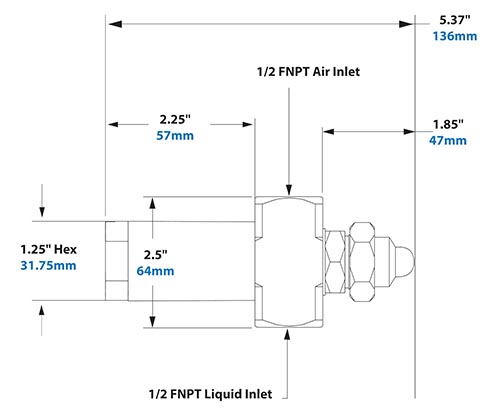

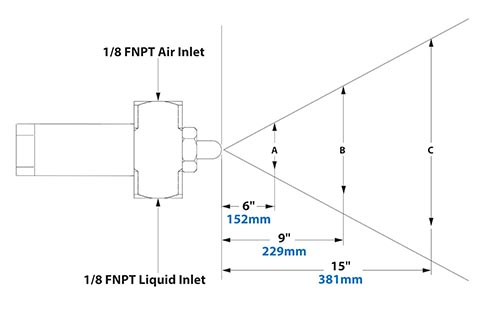

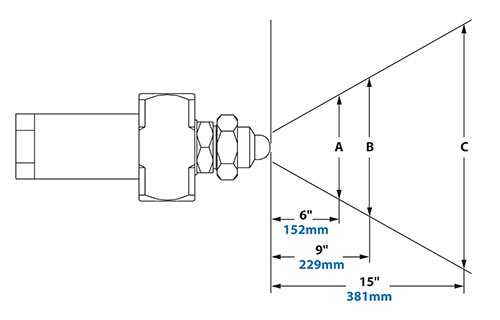

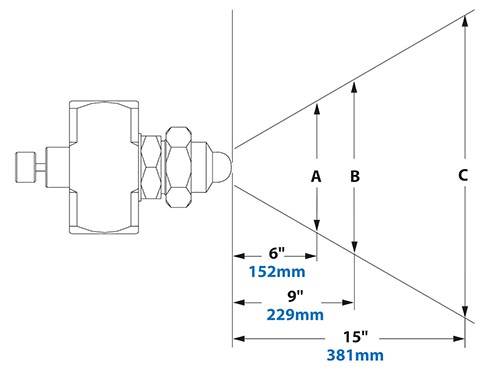

EXAIR's 1/8 FNPT, 1/4 FNPT, and 1/2 FNPT no drip internal mix flat fan pattern atomizing nozzles are designed to efficiently conserve expensive liquids and protect product finishes from drips by stopping liquid flow when compressed air is shut off. Ideal for vertical or horizontal assembly lines, these nozzles offer a broad, thin spray pattern that ensures efficient use of liquids. The output can be adjusted from a very light film to a heavy coat, making them suitable for various applications such as applying paint to hanging sheet metal or using a water mist to cool a laminate web. These nozzles cover a wide flat area, making them perfect for products moving on a conveyor. Constructed from Type 303 stainless steel for corrosion resistance, they are intended for pressure fed applications that do not require separate air and liquid control.