NEMA 4X St. St. Hazardous Loc Cabinet Cooler® Systems Only

Hazardous Location NEMA 4X (IP66) Cabinet Coolers are specially designed and approved for use in purged electrical enclosures within classified areas, including Class I Div 1, Groups A, B, C, and D; Class II Div 1, Groups E, F, and G; and Class III. Tested to meet stringent UL requirements, these cost-effective and reliable cooling systems are perfect for environments requiring safe and efficient cooling of purged electric control panels.

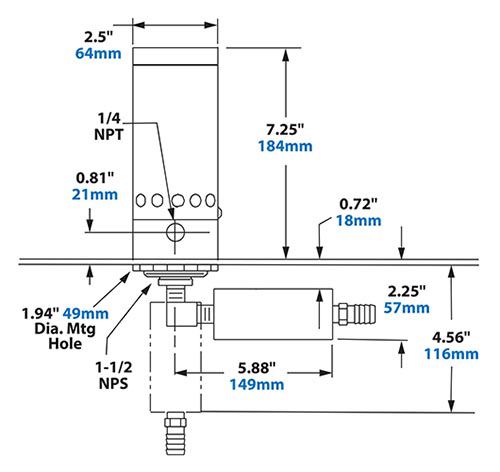

Constructed of stainless steel, these coolers are ideal for food service and corrosive environments, with cooling capacities ranging from 1,000 Btu/Hr to 5,600 Btu/Hr. They can be installed quickly through a standard electrical knockout and are available in both thermostat-controlled and continuous operation models.

NEMA 4X (IP66) Cabinet Coolers are dust-tight, oil-tight, splash-resistant, and suitable for indoor/outdoor use. They incorporate a low-pressure relief valve that seals when the cooler is not in operation, maintaining the integrity of the NEMA 4X enclosure. Each system includes a water-dirt filter separator to prevent contaminants from entering the enclosure and a cold air distribution kit for targeted air circulation.

All EXAIR HazLoc Cabinet Coolers are UL Classified and CE compliant. It's important to note that these coolers are designed to be used in conjunction with, not as a replacement for, a purged and pressurized control system.Use our Cabinet Cooler Sizing Guide to submit information online about your control panel cooling problem.

For immediate help, call our Application Engineering Department at 080 - 31681897